Our Cu-29 filament is more than 80x more conductive and significantly more cost-effective than its closest competitor. The resistivity is tested at 0.0000743 ohm/cm vs. 0.006 ohm/cm. It is compatible with the most common Fused Filament Fabrication (FFF/FDM) 3D Printers.

Pre Order Cu-29 - Until March 31st!

Don't miss out on the opportunity to get your hands on Cu-29, the world's most

highly conductive 3D printer filament! We're starting our pilot production run,

and Cu-29 will be ready to ship early in Q2.

Due to the compounding effects of inflation in the last year, we have had to

reassess our price point and account for higher costs.

But here's the good news:

We have previously stated that we would launch Cu-29 at a price point of $2500

for a 1kg spool - and we're honoring that price for all orders placed before

midnight on 31 March 2023. Take advantage of this limited-time offer now!

Simply select your filament diameter and quantity from the pre-order form and

submit your order. Don’t miss out on this exclusive opportunity to get the

highest quality conductive filament for a fraction of the cost.

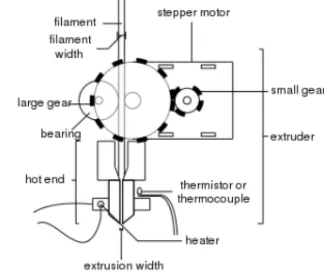

The process of AM is colloquially

referred to as 3D printing, utilizing

techniques that build up a structure.

Material Extrusion which is the most

common form of AM is further broken down

into two main methods FFF and

stereolithography (SLA). Each method has

its advantages with FFF having a wider

range of materials and SLA permitting a

higher resolution detail. FFF style printing

typically uses filaments that are melted

through an extruder head to be laid down

onto a surface. Typical printer heads are

able to generate a maximum temperature of

about 260°C to 300°C. This process

heavily favors the use of thermoplastics to

create their structures. Electrically

conductive filaments have been generated

and are available in the market but require

post processing (which can easily ruin a

print); to reach viable resistivity.

The plastic acts as a scaffold and carrier for

the desired conductive material, but

consequently introduces high resistivity.

The post processing method involves curing

the print in a vacuum oven to remove the

carriers and additives but can inadvertently

degrade the metal it is trying to precipitate

thus ruining the print.

The Kupros all metal filament avoids all of these problems.

Get In Touch

We want to hear from you. Contact us today to learn more about our business and how you can benefit from working with us.

Or if you want to preorder our future products.

info@kuprosinc.com

99 W Washington St., Loogootee, Indiana, 47553